DO NOT TOUCH

Any work on this product needs a licensed asbestos contractor.

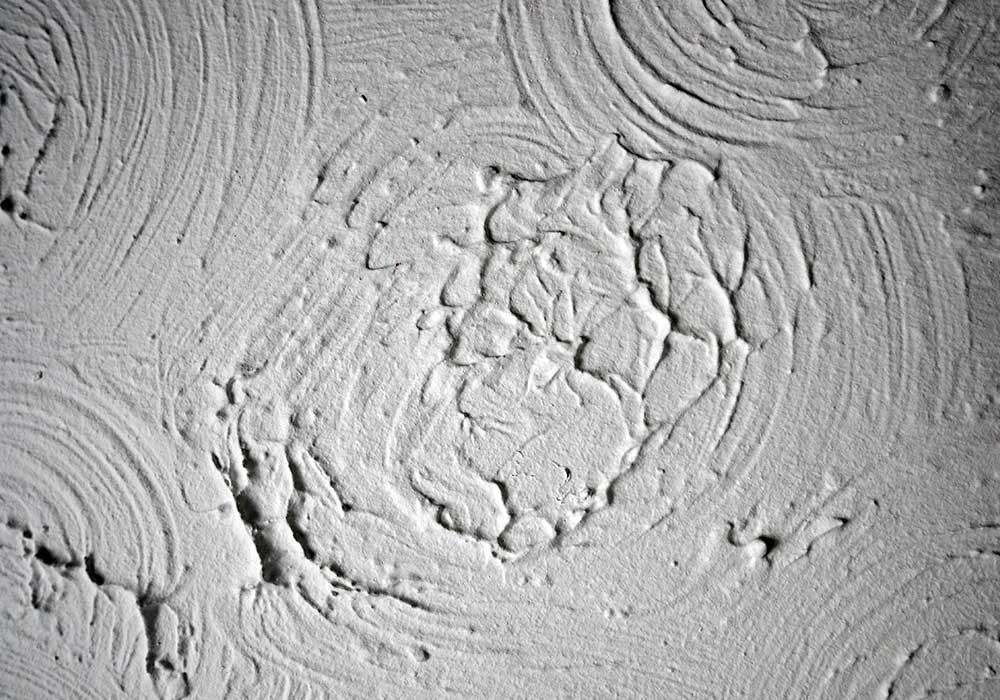

Pipe Lagging

Asbestos-containing pipe lagging, also known as asbestos pipe insulation, was a common insulation material used in plumbing and industrial applications from the early to mid-20th century. This material was favoured for its heat resistance and insulating properties but has since been recognized as a significant health hazard due to the presence of asbestos fibres. Here’s a description of asbestos-containing pipe lagging:

- Composition: Asbestos-containing pipe lagging consists of a mixture of asbestos fibres, binders, and sometimes additional materials such as cement. The asbestos fibres were used to provide thermal insulation and protect pipes from extreme temperatures.

- Applications: This type of insulation was applied to pipes in various settings, including industrial facilities, commercial buildings, and homes. It was used to reduce heat loss, maintain temperature control, and prevent condensation on pipes.

- Health Risks: The primary concern with asbestos-containing pipe lagging is the potential release of asbestos fibres when it becomes damaged, deteriorates, or is removed. Inhalation of airborne asbestos fibres can lead to severe health conditions, including lung cancer, mesothelioma, and asbestosis.

- Age and Identification: Asbestos-containing pipe lagging was commonly installed in structures constructed before the 1980s. Identifying whether pipe lagging contains asbestos requires professional testing or sampling, as asbestos fibres are not visible to the naked eye.

- Removal and Handling: Due to the significant health risks associated with asbestos, the removal of asbestos-containing pipe lagging should only be performed by licensed asbestos removal professionals, like yourself. Strict safety protocols, including containment, personal protective equipment (PPE), and thorough decontamination procedures, must be followed to minimize asbestos exposure during removal.

- Replacement: When asbestos-containing pipe lagging is discovered during renovations or demolition, it is safely removed and replaced with asbestos-free insulation materials to ensure the safety of building occupants and workers. Modern, asbestos-free insulation options are used for thermal and acoustic insulation needs.

In summary, asbestos-containing pipe lagging was once widely used for its insulation properties. However, it poses serious health risks when disturbed or deteriorated, as asbestos fibres can become airborne.